Intshayelelo kwi-iron ore

I-iron ore ngumthombo obalulekileyo wemizi-mveliso, yi-iron oxide ore, i-mineral aggregate equlethe izinto zentsimbi okanye iikhompawundi zentsimbi ezinokusetyenziswa ngokwezoqoqosho, kwaye kukho iintlobo ezininzi ze-iron ore. Phakathi kwazo, iimveliso zokunyibilikisa intsimbi ziquka ikakhulu iMagnetite, i-siderite, kunye ne-hematite njl. I-iron ikhona kwindalo njengekhompawundi, kwaye i-iron ore inokukhethwa kancinci emva kokuba i-iron ore yendalo icoliwe, igutywe, ikhethwe ngemagnethi, iflotation, kwaye ikhethwe kwakhona. Ke ngoko, i-iron ore sisixhobo esibalulekileyo kwicandelo lemveliso yentsimbi; ngokubanzi i-iron ore engaphantsi kwama-50% kufuneka idlule kwi-dressing ngaphambi kokunyibilikisa nokusetyenziswa. Okwangoku, imeko yangoku yeshishini lentsimbi edibeneyo kunye neempawu zezixhobo zezixhobo ze-iron ore zaseTshayina kufuneka ziphuculwe rhoqo kwinkqubo yokuphucula i-iron ore yaseTshayina ukuze kukhuthazwe uphuhliso olukhawulezileyo lweshishini, utyalo-mali lwezixhobo kwimisebenzi yokutyumza nokusila, iindleko zemveliso, ukusetyenziswa kombane kunye nokusetyenziswa kwentsimbi kunye nezinye izinto ziya kumisela kakhulu uphuhliso lweshishini kunye nokusebenza kakuhle kwemarike.

Ukusetyenziswa kwe-Iron ore

Iindawo eziphambili ezisetyenziswa kakhulu kwi-iron ore kushishino lwentsimbi. Kule mihla, iimveliso zentsimbi zisetyenziswa kakhulu kuqoqosho lwesizwe nakubomi bemihla ngemihla babantu, zizinto ezisisiseko ezifunekayo kwimveliso yoluntu kunye nobomi, intsimbi njengenye yezona zinto zibalulekileyo zokwakha kuqoqosho lwesizwe, ithatha indawo ebaluleke kakhulu kwaye ibe yintsika ebalulekileyo yophuhliso loluntu.

Intsimbi, imveliso yentsimbi, uhlobo, umgangatho ibisoloko iyindlela yokulinganisa ishishini lelizwe, ezolimo, ukhuselo lwesizwe kunye nesayensi kunye netekhnoloji, uphawu olubalulekileyo lophuhliso, apho intsimbi njengezinto ezisisiseko zokwenza imveliso yentsimbi, sisixhobo esibalulekileyo esixhasa lonke ishishini lentsimbi, i-iron ore idlala indima enkulu kushishino lwentsimbi, inokunyibilikiswa ibe yintsimbi yehagu, intsimbi eqinisiweyo, i-ferroalloy, intsimbi yekhabhoni, intsimbi ye-alloy, intsimbi ekhethekileyo, i-magnetite ecocekileyo nayo ingasetyenziswa njengesihluzi se-ammonia.

Ukuze kusetyenziswe ngokupheleleyo izibonelelo zezixhobo ze-iron ore, ngenxa yeempawu ze-iron ore ethambileyo, i-ore engatyebanga kangako, iiminerali ezinxulumeneyo, izinto ezintsonkothileyo ze-ore kunye nobukhulu bengqolowa ye-ore ore, iteknoloji yokubopha i-ore kunye nezixhobo zokubopha i-ore kufuneka zihambelane nexesha, ngaba singawuphucula ngokupheleleyo umgangatho weemveliso ze-iron ore, ubungakanani kunye nokusebenza kakuhle kwezoqoqosho kwamashishini?

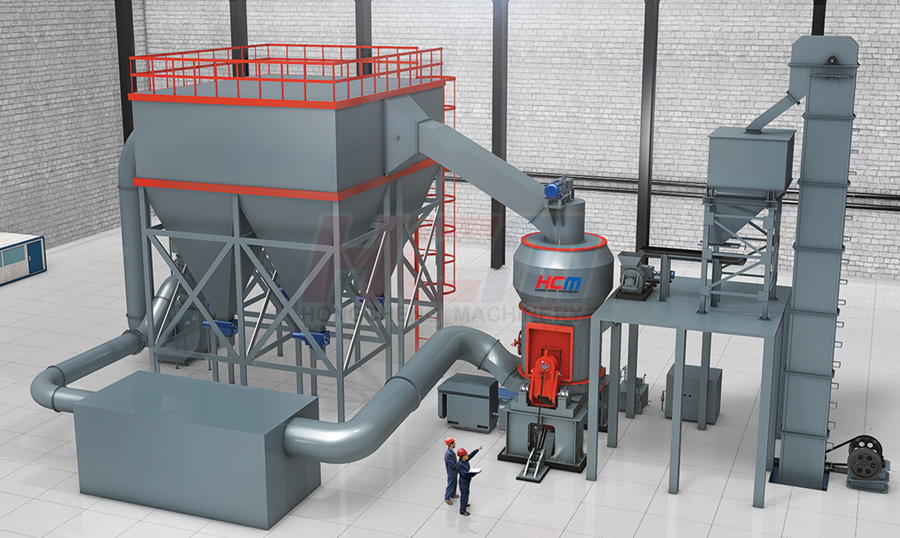

Ukuhamba kwenkqubo yokucolwa kwesinyithi

Iphepha lohlalutyo lwezithako zesinyithi

| Uhlobo lwezithako | Iqulethe iFe | Iqulethe u-O | Iqulethe i-H2O |

| I-ore yesinyithi ye-magnetite | 72.4% | 27.6% | 0 |

| I-Hematite iron ore | 70% | 30% | 0 |

| I-ore yesinyithi yeLimonite | 62% | 27% | 11% |

| Isinyithi seSiderite | Isithako esiphambili yiFeCO3 | ||

Inkqubo yokukhetha imodeli yomatshini wokwenza umgubo wesinyithi

| Inkcazo | Ukuphela kobunono bemveliso: 100-200mesh |

| Inkqubo yokukhetha izixhobo | Umatshini wokugaya othe nkqo okanye umatshini wokugaya waseRaymond |

Uhlalutyo kwiimodeli zokugaya

1. URaymond Mill, umatshini wokugaya we-HC series pendulum: iindleko zotyalo-mali eziphantsi, umthamo ophezulu, ukusetyenziswa kwamandla aphantsi, uzinzo lwezixhobo, ingxolo ephantsi; sisixhobo esifanelekileyo sokucubungula umgubo we-iron ore. Kodwa inqanaba lomlinganiselo omkhulu liphantsi xa lithelekiswa nomatshini wokugaya othe nkqo.

2. I-HLM vertical mill: izixhobo ezinkulu, ezinomthamo ophezulu, ukuhlangabezana neemfuno zemveliso ezinkulu. Imveliso inomgangatho ophezulu ongqukuva, umgangatho ongcono, kodwa iindleko zotyalo-mali ziphezulu.

3. I-HCH ultrafine grinding roller mill: I-ultrafine grinding roller mill yizixhobo zokugaya ezisebenzayo, ezonga amandla, ezingabizi kwaye ezisebenzayo zomgubo we-ultrafine ongaphezulu kwama-600 meshes.

4. I-HLMX ultra-fine vertical mill: ingakumbi kwimveliso enkulu enomthamo omkhulu we-ultrafine powder engaphezu kwama-600 meshes, okanye umthengi onemfuno ephezulu kwimo ye-powder particles, i-HLMX ultrafine vertical mill yeyona ndlela ilungileyo.

Inqanaba I: Ukutyunyuzwa kwezinto ezikrwada

Izinto ezinkulu zentsimbi zityunyuzwa yi-crusher ukuya kutsho kube bubuncinci bokutya (15mm-50mm) obunokungena kwi-grinding mill.

Inqanaba lesiBini: Ukusila

Izinto ezincinci zesinyithi ezicoliweyo zithunyelwa kwindawo yokugcina izinto nge-elevator, zize zithunyelwe kwigumbi lokusila lendawo yokusila ngokulinganayo nangobuninzi yi-feeder ukuze zisilwe.

Inqanaba lesi-3: Ukwahlulahlula

Izinto ezisiliweyo zilinganiswa ngokwenkqubo yokulinganisa, kwaye umgubo ongafanelekiyo ulinganiswa ngokwesihluzo kwaye ubuyiselwe kumatshini oyintloko ukuze usetyenziswe kwakhona.

Inqanaba V: Ukuqokelelwa kweemveliso ezigqityiweyo

Umgubo ohambelana nobunzima buhamba ngepayipi kunye negesi uze ungene kwisiqokeleli sothuli ukuze sahlulwe kwaye siqokelelwe. Umgubo ogqityiweyo oqokelelweyo uthunyelwa kwisisele semveliso egqityiweyo ngesixhobo sokuhambisa ngesango lokukhupha, uze upakishwe yi-powder tanker okanye i-automatic packer.

Imizekelo yokusetyenziswa komgubo we-iron ore

Imodeli kunye nenani lezi zixhobo: Iseti e-1 ye-HLM2100

Ukucubungula izinto ezikrwada: i-iron ore

Ubungakanani bemveliso egqityiweyo: 200 mesh D90

Umthamo: 15-20 T / h

Iinjineli zaseGuilin Hongcheng zinolwazelelelo kwaye zinoxanduva ukususela eku-odoleni ngabom, uphando lwasentsimini, ukuvelisa, ukugunyazisa ukuya ekufakeni. Abazange bagqibe nje ngempumelelo umsebenzi wokuhambisa, kodwa imeko yendawo yokusebenza kwezixhobo iyabonakala, ukusebenza kwezixhobo kuzinzile, ukusebenza kuthembekile, ukusebenza kakuhle kwemveliso kuphezulu kakhulu, kwaye ukugcinwa kwamandla kukwakhusela okusingqongileyo. Sanelisekile kakhulu kwaye siqinisekile ngezixhobo zaseHongcheng.

Ixesha lokuthumela: Okthobha-22-2021