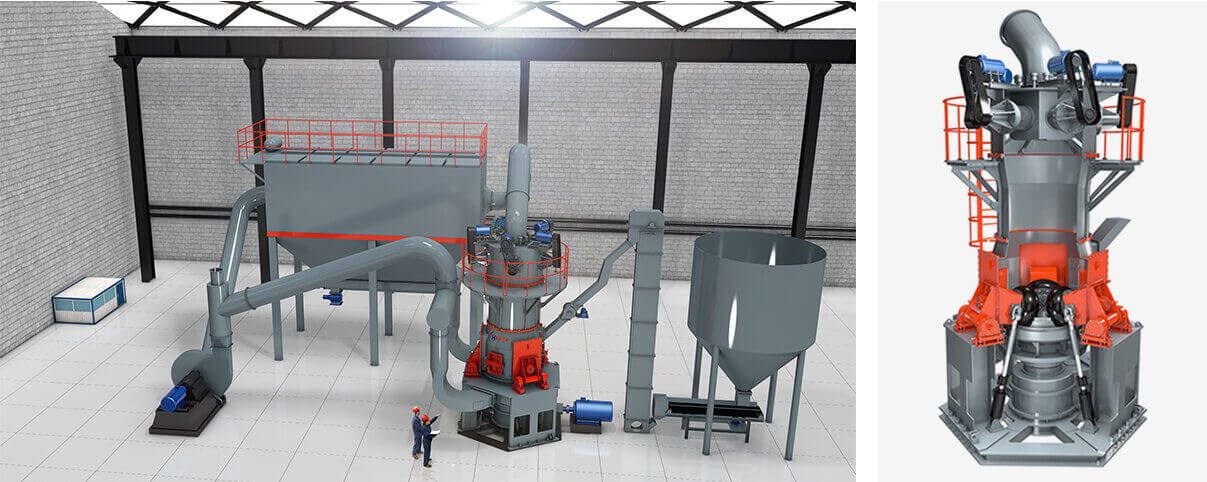

Ulwakhiwo kunye noMgaqo

siyaqhubeka nokuphucula, ukuqinisekisa umgangatho wemveliso ngokuhambelana neemfuno zemarike kunye nemigangatho yabathengi. Inkampani yethu inenkqubo yokuqinisekisa umgangatho. I-Original Factory China Talc Limestone Powder Grinding Mill yasungulwa, Inkampani yethu yakhula ngokukhawuleza ngobukhulu kunye negama ngenxa yokuzinikela kwayo ngokupheleleyo kwimveliso esemgangathweni ophezulu, ixabiso elikhulu leempahla kunye nomboneleli omkhulu wabathengi.

ukuqhubeka nokuphucula, ukuqinisekisa umgangatho wemveliso uhambelana neemfuno zemarike kunye nemigangatho yabathengi. Inkampani yethu inenkqubo yokuqinisekisa umgangatho esele imiselwe.Umatshini Wokugaya waseTshayina, Iroller Grinding Mill, Sinamava eminyaka emininzi kwimveliso yeenwele, kwaye iqela lethu le-QC eliqinileyo kunye nabasebenzi abanezakhono baya kuqinisekisa ukuba sikunika izinto zeenwele eziphezulu ezikumgangatho ophezulu kunye nomsebenzi weenwele ogqwesileyo. Uya kufumana ishishini eliphumelelayo ukuba ukhetha ukusebenzisana nomvelisi onjalo ochwepheshile. Wamkelekile intsebenziswano yakho yeodolo!

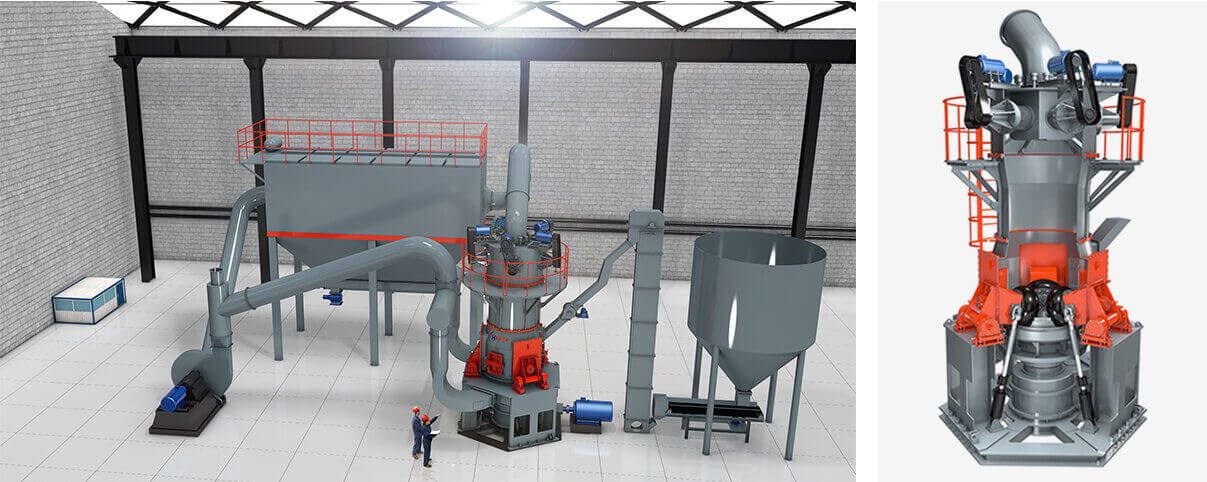

Injini iqhuba i-reducer ukuze ijikelezise idayali, izinto eziluhlaza zisiwa embindini wedayali ukusuka kwi-air lock rotary feeder. Izinto ziya emaphethelweni edayali ngenxa yempembelelo yamandla e-centrifugal kwaye ziyacolwa ngamandla e-roller kwaye zityunyuzwe phantsi kokukhupha, ukugaya kunye nokusika. Kwangaxeshanye, umoya oshushu uyavuthuzwa ujikeleze idayali uze unyuse izinto ezisemhlabeni. Umoya oshushu uya komisa izinto ezidadayo uze uvuthuze izinto ezirhabaxa ubuyele kwidayali. Umgubo ocolekileyo uya kuziswa kwi-classifier, kwaye emva koko, umgubo ocolekileyo ofanelekileyo uya kuphuma kwi-mill uze uqokelelwe ngumqokeleli wothuli, ngelixa umgubo orhabaxa uya kuwa phantsi kwidayali nge-blade ye-classifier uze uphinde ucolwe. Lo mjikelo yinkqubo yonke yokusila.

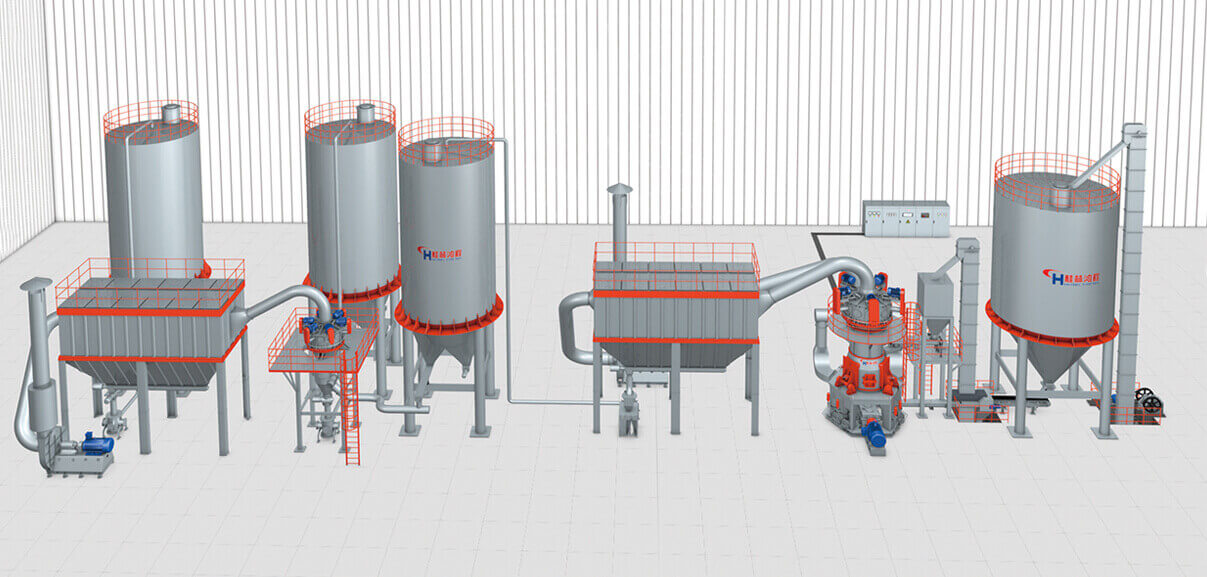

Inkqubo yokuHlela yeSibini

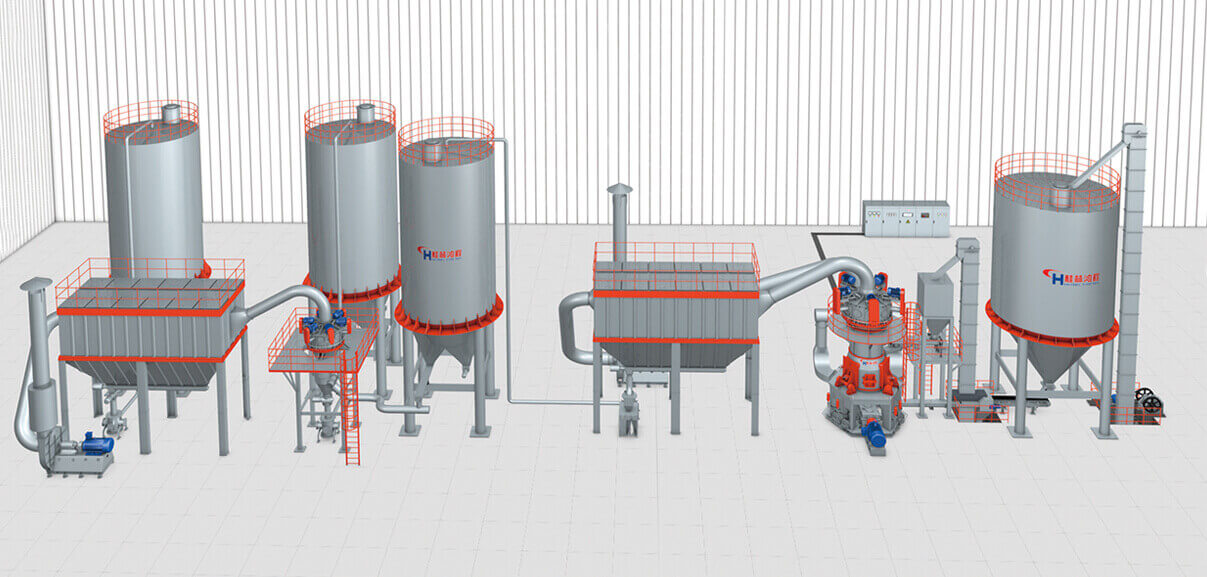

Inkqubo yokwahlulahlula yesibini ibandakanya i-superfine classifier, ifeni, umqokeleli wothuli, i-hopper, i-screw conveyor kunye nemibhobho. I-classifier yeyona matshini iphambili yenkqubo yonke. I-HLMX series superfine vertical mill inenkqubo ye-secondary classifier, ekwaziyo ukwahlula ngokufanelekileyo umgubo ocolekileyo kumgubo ocolekileyo ukuze ifumane iimveliso ezinobunono obahlukeneyo phakathi kwe-800 mesh ukuya kwi-2000 mesh.

Iimpawu zenkqubo yokwahlulahlula yesibini

Ukusebenza kakuhle kokuhlelwa: I-classifier kunye nefeni zilawulwa ngumgaqo wesantya sokuguqulwa kwamaza. Ngokulungisa isantya se-classifier kunye ne-impeller yefeni, ukuqina okuhlukeneyo kwemveliso yokugqibela ezinzileyo nethembekileyo kunokufunyanwa ngokukhawuleza. Ukusebenza kakuhle kokuhlelwa kuphezulu.

Isixhobo sokwahlulahlula ipowder esisebenza kakuhle nesigcina amandla. I-single rotor okanye i-multi-rotor isetyenziselwa ukuvelisa ubungakanani beentwana ezilungisekayo ngenxa yemfuno yokwenyani.

Uluhlu olubanzi lokucoleka: Inkqubo yokuhlela iyakwazi ukukhetha amasuntswana amancinci kwizinto ezisetyenzisiweyo. Ukucoleka kungasukela kwi-800 mesh ukuya kwi-2000 mesh. Ngenkqubo yokuhlela yesibini inokufumana ubungakanani obahlukeneyo bamasuntswana, kwaye inokufumana ubungakanani obufanayo bamasuntswana kwi-output ephezulu.

I-HLMX talc superfine powder grinding mill ineentlobo ngeentlobo zezicelo kwiindawo zokwakha, ii-coating, iphepha, irabha, amandla ombane, i-metallurgy, isamente, iikhemikhali, amayeza, ukutya njalo njalo. Ineempawu zokusila ngokufanelekileyo, kulula ukuzigcina, iindleko zokusebenza eziphantsi, iindleko zemali ephantsi, umgangatho ozinzileyo, ukhuseleko lokusingqongileyo kunye nenqanaba eliphezulu lokuzenzekelayo. Icetyiswa ekucutshungulweni kwe-talc kunye nezinye izinto ezingezizo zesinyithi ezinobunzima be-Mohs obungaphantsi kwe-7 kunye nokufuma okungaphantsi kwe-6% yezinto zeminerali ezingezizo zesinyithi.

I-HLMX talc superfine powder grinding mill ineentlobo ngeentlobo zezicelo kwiindawo zokwakha, ii-coating, iphepha, irabha, amandla ombane, i-metallurgy, isamente, iikhemikhali, amayeza, ukutya njalo njalo. Ineempawu zokusila ngokufanelekileyo, kulula ukuzigcina, iindleko zokusebenza eziphantsi, iindleko zemali ephantsi, umgangatho ozinzileyo, ukhuseleko lokusingqongileyo kunye nenqanaba eliphezulu lokuzenzekelayo. Icetyiswa ekucutshungulweni kwe-talc kunye nezinye izinto ezingezizo zesinyithi ezinobunzima be-Mohs obungaphantsi kwe-7 kunye nokufuma okungaphantsi kwe-6% yezinto zeminerali ezingezizo zesinyithi.

I-Hcmilling (iGuilin Hongcheng) nguMvelisi kunye noMboneleli we-grinding mill owaziwayo obonelela ngezixhobo zokugaya ezikumgangatho ophezulu kubathengi ngamaxabiso afanelekileyo. Sizimisele ukubonelela nge-grinding mill engcono kakhulu eya kunceda abathengi ukuba bavelise ixabiso elingakumbi.

Singathanda ukukucebisa ngemodeli yomatshini wokusila ofanelekileyo ukuqinisekisa ukuba ufumana iziphumo zokusila ozifunayo. Nceda usixelele le mibuzo ilandelayo:

1. Izinto zakho ezikrwada?

2. Ubunzima obufunekayo (i-mesh/μm)?

3. Umthamo ofunekayo (t/h)?

I-HLMX talc superfine powder grinding mill ineentlobo ngeentlobo zezicelo kwiindawo zokwakha, ii-coating, iphepha, irabha, amandla ombane, i-metallurgy, isamente, iikhemikhali, amayeza, ukutya njalo njalo. Ineempawu zokusila ngokufanelekileyo, kulula ukuzigcina, iindleko zokusebenza eziphantsi, iindleko zemali ephantsi, umgangatho ozinzileyo, ukhuseleko lokusingqongileyo kunye nenqanaba eliphezulu lokuzenzekelayo. Icetyiswa ekucutshungulweni kwe-talc kunye nezinye izinto ezingezizo zesinyithi ezinobunzima be-Mohs obungaphantsi kwe-7 kunye nokufuma okungaphantsi kwe-6% yezinto zeminerali ezingezizo zesinyithi.

I-HLMX talc superfine powder grinding mill ineentlobo ngeentlobo zezicelo kwiindawo zokwakha, ii-coating, iphepha, irabha, amandla ombane, i-metallurgy, isamente, iikhemikhali, amayeza, ukutya njalo njalo. Ineempawu zokusila ngokufanelekileyo, kulula ukuzigcina, iindleko zokusebenza eziphantsi, iindleko zemali ephantsi, umgangatho ozinzileyo, ukhuseleko lokusingqongileyo kunye nenqanaba eliphezulu lokuzenzekelayo. Icetyiswa ekucutshungulweni kwe-talc kunye nezinye izinto ezingezizo zesinyithi ezinobunzima be-Mohs obungaphantsi kwe-7 kunye nokufuma okungaphantsi kwe-6% yezinto zeminerali ezingezizo zesinyithi.