Iglasi yenkunkuma luhlobo lwenkunkuma yasekhaya, ukubakho kwayo akupheleli nje ekubangeleni umonakalo nokuphazamiseka kwimveliso nakubomi babantu, kodwa kuzisa nongcoliseko kwindalo esingqongileyo, kuthathe umhlaba oxabisekileyo, kwaye kwandisa umthwalo wendalo esingqongileyo. Kuqikelelwa ukuba iTshayina ivelisa malunga neetoni ezi-3.2 zezigidi zeglasi yenkunkuma minyaka le, ebalelwa malunga ne-2% yenani lilonke lenkunkuma eqinileyo kamasipala. Ngokuphuculwa kwamandla esizwe apheleleyo kunye nokuphuculwa kwemigangatho yokuphila yabantu, inani lilonke leglasi yenkunkuma nalo liye landa. Ngokuphathelele ukuphinda kusetyenziswe iglasi yenkunkuma, amanye amazwe aphuhlileyo e-United Kingdom nase-United States afumene iziphumo ezimangalisayo. Amazwe aseYurophu naseMelika asebenzise iglasi yenkunkuma ngempumelelo kwiiprojekthi zokwakha, okuyindlela esebenzayo yokusebenzisa inani elikhulu leglasi yenkunkuma. Ngenxa yokuba zonke iintlobo zeglasi yenkunkuma azidingi kuhluzwa, akukho mfuneko yombala. Umzekelo, iglasi yenkunkuma icutshungulwa njengezinto zokuhombisa isakhiwo kwiMosaic. Njengomvelisi weglasi yenkunkuma, iglasi yenkunkuma eyenziwe yiHCM Machinery inika uncedo olufanelekileyo lwezixhobo zokuphinda kusetyenziswe iglasi yenkunkuma. Namhlanje, siza kwazisa inkqubo yokuvelisa iglasi yenkunkuma yokuphinda kusetyenziswe iMosaic.

1. Ukuzuza ilitye le-phosphate: Ukuzuza ilitye le-phosphate linyathelo lokuqala ekucutshungulweni kwelitye le-phosphate, elijolise ekuhlukaniseni iiminerali eziluncedo kwizinto ezingcolileyo kwilitye le-phosphate ngeendlela ezibonakalayo nezekhemikhali. Iindlela eziqhelekileyo zokuzuza ziquka ukwahlula umxhuzulane, ukutyibilika kunye nokwahlula imagnethi. Ukwahlula umxhuzulane kusebenzisa umahluko wobuninzi beeminerali kwi-ore ukuze kwahlulwe, ukutyibilika kusebenzisa umahluko wokubutha kweeminerali kwi-ore ukuze kwahlulwe, kwaye ukwahlula imagnethi kusebenzisa umahluko wobumagnethi weeminerali kwi-ore ukuze kwahlulwe.

2. Ukutyumza nokucola ilitye le-phosphate: ilitye le-phosphate emva kokuhluzwa, kufuneka lityumzwe kwaye lilungiswe, ukuze kukhutshwe ngcono iiminerali eziluncedo kwi-ore. Ukutyumza kudla ngokusetyenziswa i-jaw crusher, i-cone crusher kunye nezinye izixhobo ukuqhekeza ilitye le-phosphate libe bubungakanani obufanelekileyo be-particle. Ukutyumza kukusetyenziswa komatshini omkhulu wokuvelisa nokucubungula i-phosphate powder ukusika i-ore etyumkileyo, ukuze ihlangabezane neemfuno ezifunekayo zobuchule.

3. Ukucocwa kwelitye le-phosphate: Ukucocwa kwelitye linyathelo elibalulekileyo ekucutshungulweni kwelitye le-phosphate, apho izithako eziluncedo ezifana ne-phosphate zinokucocwa kwi-ore. Iindlela zokucocwa ezisetyenziswa rhoqo ziquka ukucocwa kwe-acid, ukucocwa kwe-alkali kunye nokucocwa kwe-oxidation. Ukucocwa kwe-acid kusebenzisa isisombululo se-acid ukucocwa kwe-phosphate, ukucocwa kwe-alkaline kusebenzisa isisombululo se-alkaline ukucocwa kwe-phosphate, kwaye ukucocwa kwe-oxidative kusebenzisa i-oxidizing agent ukucocwa kwe-phosphate.

4. Ukuna kunye nokuhluzwa kwee-phosphate ores: Emva kokukhuhla, isisombululo sezinto eziluncedo ezifana ne-phosphate kufuneka sihluzwe kwaye sihluzwe ukuze kwahlulwe iimveliso ze-phosphate eqinileyo. Ukuna kukusetyenziswa kwe-precipitating agent ukuguqula i-phosphate component yesisombululo ibe yi-solid precipitate, kwaye ukuhluzwa kukwahlulwa kwe-sediment kwisisombululo ngezixhobo zokucoca.

5. Ukomisa nokutshiza ilitye le-phosphate: Emva kokuba i-sediment ihluziwe, kufuneka yomiswe kwaye itshizwe ukuze kufunyanwe imveliso ye-phosphate egqityiweyo. Ukomisa kukusetyenziswa kwezixhobo zokomisa ukuze kuphume amanzi kwi-sediment, kwaye ukutshiza kukomisa i-sediment kubushushu obuphezulu, ukuze yenze amasuntswana e-phosphate axineneyo.

6. Unyango lwe-phosphate ore tailings: Inkqubo yokucubungula i-phosphate ore iya kuvelisa inani elithile le-tailings, i-tailings iqulethe iiminerali ezingakhutshwanga kunye nokungcola. Ukuze kuncitshiswe ungcoliseko lokusingqongileyo kunye nokuchithwa kwezixhobo, i-tailings kufuneka iphathwe. Iindlela eziqhelekileyo zonyango lwe-tailings ziquka ukuqokelela i-tailings, ukuphinda usebenzise i-tailings kunye nokusetyenziswa okubanzi kwe-tailings.

Inkqubo yokuvelisa i-Mosaic yeglasi ephinda isetyenziswe: indlela yokusila kunye nendlela yokunyibilikisa zisetyenziswa ngokubanzi, kwaye indlela yokuvelisa indlela yokusila kunye ne-ceramic Mosaic ziyafana ngokusisiseko. Inkqubo ephambili yokuvelisa kukucola iglasi engcolileyo nge-waste glass mill ukuze kuhlangatyezwane neemfuno zobukhulu be-glass powder, uze wongeze inani elithile le-agent enamathelayo (inorganic okanye organic can) kunye ne-agent yokufaka imibala okanye i-agent yokususa umbala, kunye ne-mixer ukuze ixutywe ibe yi-compound efanayo. Umxube ucinezelwa kwiimo ezahlukeneyo zejometri ngendlela yokucinezela eyomileyo, kwaye umzimba owomileyo uthunyelwa kwi-roller oven, kwi-push plate oven kunye ne-tunnel oven enobushushu obuyi-800-900 degrees Celsius ukuze kucinywe. Ngokubanzi, ihlala kwindawo yobushushu bokusila kangangeeyure eziyi-1.5-2.5. Ukupholisa iimveliso ngaphandle kwe-oven ukuze zihlolwe, zibekwe, zomiswe, zihlolwe, zipakishwe, zigcinwe okanye zisetyenziswe kwifektri, iimveliso ezingafanelekiyo ziyaphinda zisetyenziswe. Indlela yokunyibilikisa isekelwe kwiglasi emdaka (ubungakanani babantu yi-25-60%) njengezinto eziphambili, kongeza inani elithile lesanti ye-silica, i-feldspar, i-limestone, i-soda ash kunye ne-emulsion agent, i-agent yokufaka imibala ngokusebenzisa indlela yokugaya iglasi yenkunkuma ibe ngumgubo ofanayo, ize ifike kwi-oven yokunyibilikisa eshushu kakhulu (ubushushu bokunyibilikisa yi-1400-1500) ukuze inyibilike ibe lulwelo lweglasi olufanayo. Ulwelo lweglasi lungena kwikhalenda kwaye lucinezelwe kwibhloko yeglasi enobukhulu obuthile kunye nemilo, ethunyelwa kwi-oven yokunyibilikisa. Iimveliso ezifakwe kwi-anneal zingagcinwa okanye zihanjiswe emva kokuhlolwa, ukubekwa kunye nokupakishwa.

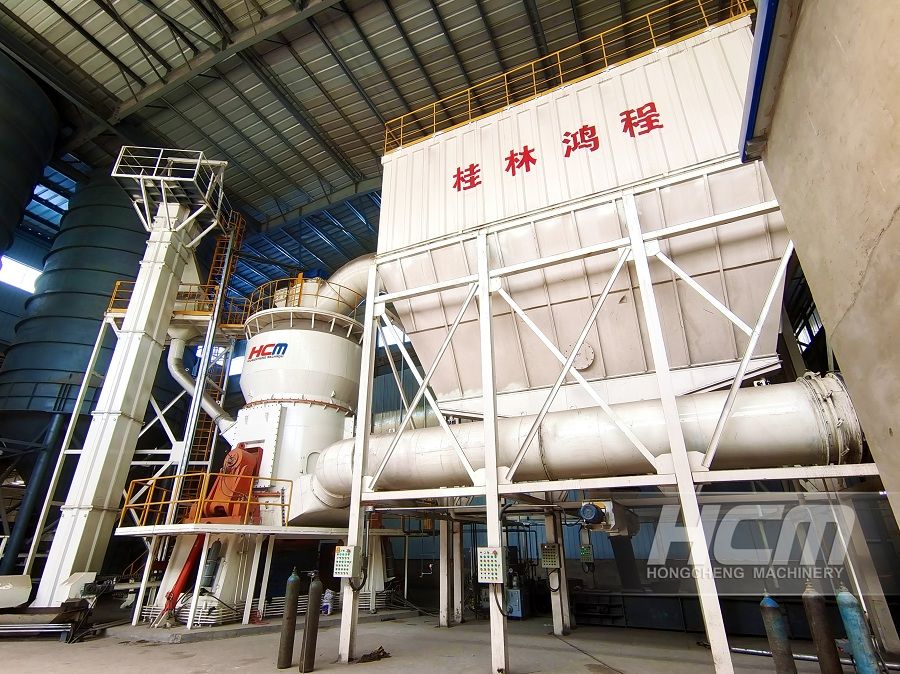

Ukuphinda usebenzise iglasi yenkunkuma Iiglasi zemosaic zisekelwe ekugayeni iglasi yenkunkuma ibe ngumgubo weglasi. I-Waste glass mill sisixhobo sokuvelisa ukucubungula umgubo weglasi. I-waste glass mill eyenziwe yiOomatshini beHCM has HC, HCQ and other models, which can process 80-400 mesh glass powder with large output, low energy consumption, small equipment area and simple technology. If you have waste glass recycling needs, welcome to call us to learn more about waste glass mill equipment:hcmkt@hcmilling.com

Ixesha leposi: Jan-08-2024