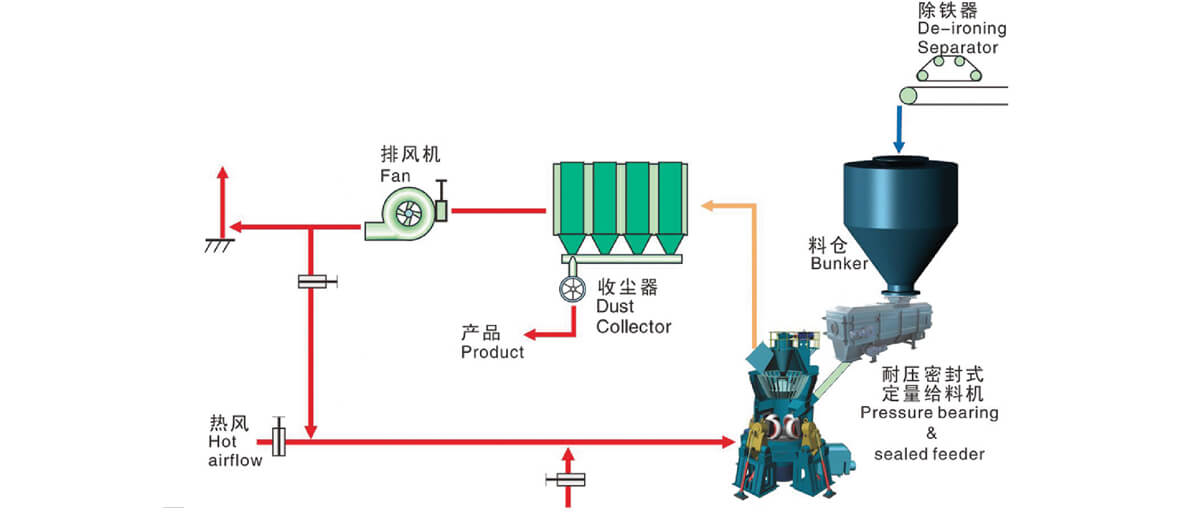

Imveliso yokugqibela inomgangatho ozinzileyo. Ixesha elifutshane lokuhlala kwezinto eziza kugaywa linokuqinisekisa ukuba ziyafana kwaye zithambile. Umxholo omncinci wesinyithi kulula ukuwususa ukuqinisekisa ukuba zimhlophe kwaye zicocekile.

qonda

UYAYIFUNA ISICULULO?Ukuze ufumane ulwazi oluthe kratya malunga nomatshini wokugaya okanye isicelo sekowuteshini nceda unxibelelane nathi.

UphandoQhagamshelana nathi

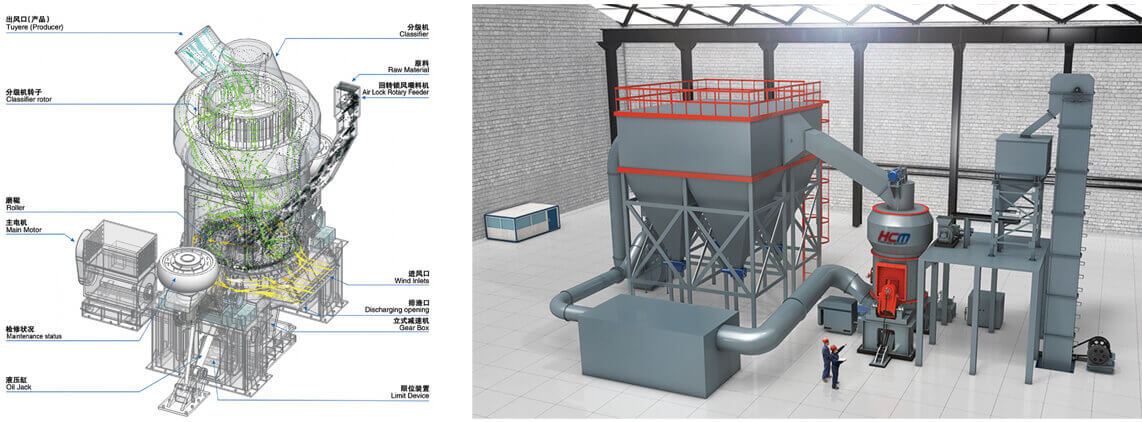

Wamkelekile ku Guilin HongchengIGuilin HongCheng Mining Equipment Manufacture Co., Ltd.

- Ifowuni:86-15107733434

- Idilesi:Yangtang Shanshui Industrial Park, Xicheng yoPhuhliso lwezoQoqosho Zone, Guilin City, kwiPhondo Guangxi, China

- I-imeyile:hcmkt@hcmilling.com

- Ifowuni:+91 97125 28918

- I-imeyile:hgvala@gmail.com

Umlawuli wentengiso waseIndiya

© Ilungelo lokushicilela - 2010-2025: Onke Amalungelo Agciniwe.Iimveliso ezishushu - Imephu yesiza

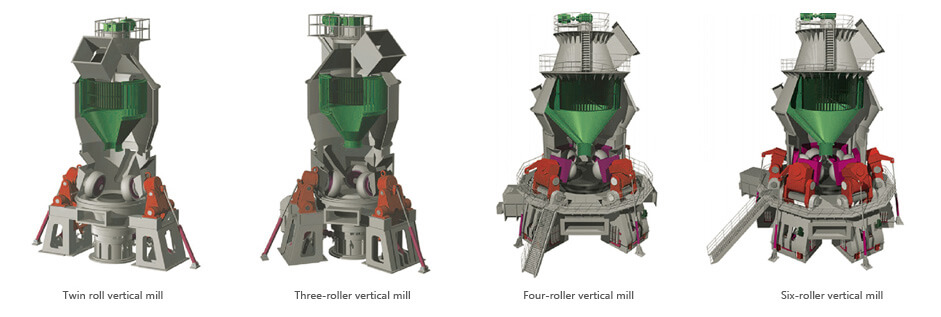

Ukugaya Amalahle, Umatshini Wokugaya Omhle Kakhulu, I-Ultra Fine Mill, I-Petroleum Coke Vertical Roller Mill, Isitshizi seMill, Umatshini Wokugaya Ipeyinti Yomgubo Ovela Kumthengisi WaseTshayina,

Ukugaya Amalahle, Umatshini Wokugaya Omhle Kakhulu, I-Ultra Fine Mill, I-Petroleum Coke Vertical Roller Mill, Isitshizi seMill, Umatshini Wokugaya Ipeyinti Yomgubo Ovela Kumthengisi WaseTshayina,